The manufacturing landscape is rapidly evolving, with automation and robotics playing an increasingly critical role in maintaining competitiveness. Large manufacturers have long reaped the benefits of automation, optimizing efficiency and throughput with advanced robotic systems. However, small-to-mid-sized manufacturers (SMMs) face unique hurdles in adopting robotics, including budget constraints, workforce readiness, and the need for scalable, flexible solutions.

Fortunately, advancements in collaborative robots (cobots) and service robots, along with emerging business models like Robotics-as-a-Service (RaaS), are breaking down these barriers. By adopting cost-effective automation, SMMs can tackle operational challenges, boost productivity, and remain competitive in a rapidly evolving industry.

The Need for Scalable Automation in Small-to-Mid Size Manufacturers

SMMs operate in a high-pressure environment where efficiency, quality, and cost-effectiveness determine long-term success. However, several industry-wide challenges are accelerating the need for automation, pushing manufacturers to seek smarter, more adaptable solutions that can help them remain competitive in an evolving market.

- Competitive pressures: Larger manufacturers continue to drive down costs through automation, making it difficult for SMMs to compete without similar efficiencies.

- Labor shortages and skills gaps: Approximately 20.6% of manufacturing plants in the United States failed to produce at full capacity through Q3 2024. An insufficient supply of labor or labor skills were cited as key contributors.

- Demand for high-mix, low-volume production: Traditional automation systems are often rigid and designed for high-volume production. SMMs require flexible solutions that can handle frequent product changes and small batch sizes.

By adopting scalable automation solutions, SMMs can enhance productivity and future-proof their operations against market volatility and workforce challenges. Investing in flexible robotics enables manufacturers to respond swiftly to shifting customer demands, reduce reliance on manual labor, and maintain a competitive edge in an increasingly automated industry. As technology continues to advance, integrating automation will become a crucial strategy for long-term growth and resilience.

.jpg)

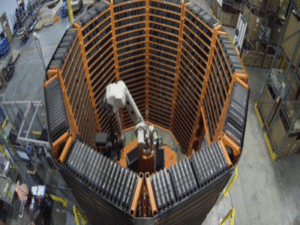

One example is DEONET, a small promotional products manufacturer, which integrated an ABB YuMi cobot into its assembly process to handle small-batch, high-mix production efficiently. By automating glue application and assembly tasks, DEONET increased production capacity to 3,000 parts per day while maintaining high quality. The ability to automate without large-scale infrastructure changes highlights how SMMs can benefit from flexible automation solutions.

Overcoming Budget Constraints with Robotics-as-a-Service (RaaS)

For many small-to-mid-sized manufacturers (SMMs), the high upfront costs of automation — spanning hardware, installation, software, and training — create a major barrier to adoption. The financial risk of investing in robotics that may require future upgrades or fail to adapt to evolving production needs further complicates the decision. As a result, many SMMs struggle to compete with larger manufacturers that have already integrated automation into their operations.

What Is Robotics-as-a-Service?

For SMMs, integrating automation can be challenging due to high upfront costs associated with hardware, installation, software, and workforce training. RaaS provides a flexible, subscription-based model that allows businesses to adopt automation without the need for large capital investments. By paying only for the robotics solutions they need, manufacturers can scale automation gradually, adapting to production demands without the financial burden of ownership.

How RaaS Makes Automation More Accessible

- Lower upfront costs: Instead of purchasing robots outright, manufacturers pay a subscription or leasing fee, spreading costs over time.

- Scalability: Companies can scale their automation efforts incrementally, expanding as demand grows.

- Maintenance and support: Many RaaS providers include ongoing maintenance and software updates, reducing the burden on internal teams.

By leveraging RaaS, SMMs can adopt automation at a pace that aligns with their growth, ensuring they remain competitive without overextending their budgets. This model makes automation financially feasible and allows companies to experiment with different robotic applications before committing to full-scale deployment. As more manufacturers embrace RaaS, the accessibility of advanced robotics continues to expand, leveling the playing field for SMMs looking to enhance efficiency and future-proof their operations.

RaaS was key for AA Precision Tooling, which partnered with A3 member Acieta to implement a robotic machining cell. Initially hesitant due to cost concerns, the company saw a 60% increase in output after deployment while reducing scrap and attracting new customers. This highlights how small manufacturers can successfully adopt automation without significant capital expenditures.

Workforce Challenges and Upskilling for Robot Integration

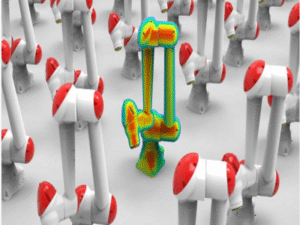

One common misconception of automation is that it replaces jobs. In reality, robotics augments human labor, allowing workers to focus on higher-value tasks while robots handle repetitive, physically demanding, or hazardous operations.

Training Programs for Human-Robot Collaboration

As robotics become more integrated into small-to-mid-sized manufacturing operations, ensuring a well-trained workforce is essential for maximizing automation benefits. While robotics can streamline production, human expertise remains critical for programming, monitoring, and maintaining these systems. Providing robotics training helps employees transition into programming, maintenance, and supervisory roles, ensuring job security while increasing operational efficiency. Companies that prioritize education and hands-on training create a workforce that is comfortable working alongside robots and capable of optimizing automation for long-term success.

- Reskilling operators: Many workers may not have prior experience with automation, making it essential to provide training on programming, monitoring, and troubleshooting robotic systems. Hands-on instruction in robotic interfaces, task sequencing, and maintenance procedures ensures employees can confidently oversee automated processes and prevent downtime.

- Collaborative training: Unlike traditional industrial robots, cobots are designed to work safely alongside humans. Training should focus on best practices for human-robot interaction, including safety protocols, task delegation, and workflow integration. Employees who understand cobot behavior and limitations can work more efficiently and ensure smooth collaboration.

- Partnerships with technical institutions: Manufacturers can accelerate workforce development by collaborating with trade schools, universities, and industry associations. These partnerships provide access to specialized training programs, certification courses, and hands-on learning opportunities tailored to real-world manufacturing environments.

By investing in structured training programs, SMMs can enhance workforce adaptability, improve productivity, and foster a culture of continuous learning. Well-trained employees are more confident in working with automation and play a key role in driving innovation and efficiency within modern manufacturing operations.

How Can SMM Manufacturers Strengthen Workplace Safety and Boost Employee Satisfaction?

Beyond financial and workforce considerations, automation plays a critical role in workplace safety — an ongoing concern for SMMs. Automation reduces the risk of injury by taking on repetitive, physically demanding, and hazardous tasks while improving overall working conditions. Hinode Co., for example, deployed Yaskawa industrial robots for deburring, which halved processing time while eliminating hazardous manual grinding tasks. This improved efficiency and worker well-being, demonstrating how robotics can enhance safety and productivity.

CTO Robotics

CTO Robotics is a global media and consulting company dedicated to robotics, automation, artificial intelligence, and emerging technologies. We create high-impact content that reaches engineers, decision-makers, and innovators worldwide. Through articles, videos, social media campaigns, and community-driven storytelling, we help companies showcase their technologies, strengthen their brand, and connect with the right audience. Much like Interesting Engineering or Wevolver, our mission is to bridge the gap between technology providers and industry professionals — turning innovation into visibility, and visibility into growth. 👉 Whether you are launching a new product, building your brand, or looking for global recognition, CTO Robotics is your media partner for exposure, credibility, and business opportunities.

All stories by: CTO Robotics

0 Comments