Artificial intelligence (AI), machine learning, and industrial automation are changing how manufacturing and production facilities work. Predictive ma intenance (PdM), which was once a pilot project, is now a strategic capability that delivers measurable gains in equipment reliability, asset lifecycle, and system-wide efficiency across complex industrial environments.

intenance (PdM), which was once a pilot project, is now a strategic capability that delivers measurable gains in equipment reliability, asset lifecycle, and system-wide efficiency across complex industrial environments.

AI-enabled PdM allows organizations to make maintenance decisions based on real-time asset behavior by moving from reactive or time-based maintenance to predictive, data-driven methodologies. Advanced machine learning models ingest and interpret high-frequency sensor data such as vibration signatures, thermal fluctuations, current profiles, and acoustic patterns. These insights detect early indicators of mechanical degradation and allow maintenance to be precisely timed and targeted. This results in minimizing unplanned downtime and maximizin operational continuity.

Core Capabilities and Scalable Architecture

AI-driven predictive maintenance combines advanced functionality with scalable system design. The core capabilities include real-time anomaly detection, failure mode prediction through supervised learning, remaining useful life (RUL) estimation, root cause analysis from multi-sensor data, and autonomous scheduling tied to ERP systems.

Scalability is achieved through a layered architecture with edge AI devices for local processing, industrial IoT platforms for data aggregation, retrainable ML pipelines, digital twins for simulation, and integrated maintenance systems for automated workflows. Together, these elements turn maintenance into a dynamic insight-led function that adapts to complexity without straining the infrastructure.

AI-Driven Operational Efficiency

Predictive maintenance is part of a broader AI trend optimizing equipment usage, energy consumption, and workflow coordination. These systems integrate real-time machine data with production context, such as batch schedules or environmental conditions, to offer insights that boost overall equipment effectiveness (OEE).

AI recommendations include but are not limited to:

- Load-balanced scheduling: Reduces machine stress and extends lifespan

- Energy optimization: Minimizes waste during peak usage

- “Wear-aware” workflow adjustments: Distributes tasks to prevent component overload

Leading manufacturers are already applying predictive maintenance at scale to enhance efficiency, reduce costs, and align asset performance with broader operational goals.

IBM’s Watson Supply Chain integrates PdM data into inventory and logistics planning, aligning physical performance with supply chain agility. This synchronization reduces lead times for critical components and ensures maintenance resources are deployed where they yield the greatest return. By linking asset health with production planning, AI enables a unified strategy that improves throughput, responsiveness, and operational resilience.

Insights Hub, an IoT platform from Siemens, leverages machine learning algorithms to analyze patterns and detect anomalies in performance data collected from equipment on the factory floor. Identifying anomalies and scheduling maintenance before they become points of failure improves reliability and the bottom line. As a result, manufacturers report improved Overall Equipment Effectiveness (OEE) and reduced maintenance costs by up to 30%.

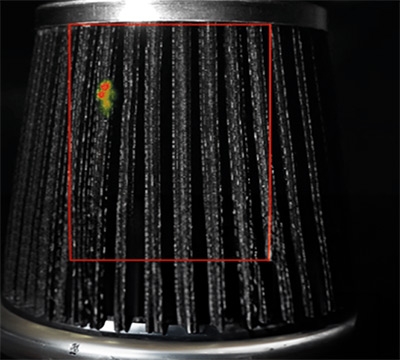

Edge AI

Industrial environments require sub-second response times, low latency in low connectivity zones and data privacy. Edge AI makes real-time decisions at the machine level without going to the cloud.

Benefits:

- Faster anomaly detection and response time: Take immediate action like shutdowns or load reductions in milliseconds, which are critical in safety applications.

- Resilience during network outages: Utilize full diagnostic and control functionality even when cloud or central systems are down.

- Less bandwidth usage through local processing: Only send essential summaries and alerts to central systems, reduce data overload, and use network infrastructure more efficiently.

- Better data security and regulatory compliance: Keep machine and operational data on site, meet data sovereignty requirements, and reduce exposure to external threats.

Numurus’ edge AI solutions highlight how predictive maintenance capabilities can be extended to demanding environments like maritime robotics, where latency, connectivity, and integration challenges make cloud-based systems impractical. In collaboration with Ocean Aero, Numurus supplied NEPI-enabled edge-compute platforms for the TRITON autonomous surface and underwater vehicles, enabling real-time threat detection and onboard AI processing without reliance on cloud connectivity. Ocean Aero integrated multiple directional cameras and AI models within six months, demonstrating fully automated maritime domain awareness. This deployment highlights how edge AI can accelerate development cycles, reduce operator dependency, and enable predictive, autonomous operations — even in isolated, high-risk environments.

Predictive Maintenance in Construction

Predictive Maintenance in Construction

Industrial AI is creeping into fast-paced environments like construction as well, where unplanned equipment failures and resource inefficiencies can cause significant delays. Companies like Raise Robotics deploy intelligent systems that enhance automation, situational awareness, and on-site responsiveness. These go beyond basic task automation by putting intelligence into core field operations so you can make more responsive, data-driven decisions in the following ways:

- Blueprint analysis automates identification of service critical components like filters and seals across architectural plans, so you don’t have to. Reduces human oversight and streamlines maintenance prep.

- Robotic assistants do repetitive or high-risk tasks like drilling or facade work while monitoring tool wear, force feedback, and operating temperature to catch early signs of degradation.

- Dynamic scheduling connects real-time site data and inspection findings to task planning software so maintenance intervals and resource assignments are updated as conditions change.

These put maintenance into daily operations for safer, more efficient, and more accurate planning. Maintenance becomes a flexible, data-driven process that adapts to site demands and supports higher overall performance.

Sustainability Through Smarter Maintenance

Predictive maintenance helps with essential initiatives such as industrial sustainability by reducing unnecessary consumption of resources, minimising waste, and long-term asset management. As organizations focus more on environmental, social, and governance (ESG) goals, AI-based maintenance is key to compliance and competitive advantage. These deliver tangible benefits across several areas:

- Avoid replacing parts prematurely by making service decisions based on actual equipment condition rather than static schedules, reducing material waste and overstocking.

- Extend equipment life by detecting faults early, optimizing usage patterns, delaying capital expenditure, and reducing the environmental impact of new equipment manufacturing.

- Use less energy by minimising emergency stops, which often require energy-intensive restarts, system purges, or temporary redundancies that increase baseline consumption.

- Reduce carbon emissions from spare parts in manufacturing and logistics by streamlining supply chain demand and avoiding expedited shipping or unnecessary warehousing of components.

Platforms like ABB’s Ability integrate sustainability metrics into operational dashboards, linking maintenance performance with environmental impact. Across manufacturing, maritime, and construction, AI-driven maintenance supports systems that are more efficient, reliable, and environmentally responsible. Each insight, adjustment, and avoided failure builds a more sustainable industrial ecosystem.

Challenges and Best Practices

Despite the benefits, predictive maintenance has some real challenges. Many legacy systems don’t have the necessary sensors or digital interfaces, so you must retrofit or add data translation layers to them. Cultural resistance can also be a barrier, as oftentimes, maintenance teams are unfamiliar with AI-driven workflows and need clear training and ROI goals. Predictive models must also be customized to adapt to highly variable equipment conditions, and the upfront investment in infrastructure, sensors, and AI platforms can be significant.

To overcome these hurdles, successful organizations take a phased approach, starting with pilot programs on high-impact assets, scaling up gradually with modular architectures. Continuous model retraining ensures accuracy over time, and cross-functional collaboration between IT, maintenance, and operations helps to embed predictive analytics into everyday workflows. When part of a broader digital transformation, predictive maintenance becomes not just a tool but a long-term competitive advantage.

The Future of Predictive Maintenance

Industrial AI has evolved from an emerging concept into essential infrastructure, redefining how organizations manage performance, risk, and sustainability at scale. Predictive maintenance stands at the forefront of this transformation, demonstrating how intelligent systems can elevate asset management into a strategic engine for operational excellence.

In the factories of the future, machines will do more than just operate. They will anticipate failures, adapt to changing demands, and continuously optimize their performance. Predictive maintenance is not merely a component of this shift; it is the foundation enabling it.

CTO Robotics

CTO Robotics is a global media and consulting company dedicated to robotics, automation, artificial intelligence, and emerging technologies. We create high-impact content that reaches engineers, decision-makers, and innovators worldwide. Through articles, videos, social media campaigns, and community-driven storytelling, we help companies showcase their technologies, strengthen their brand, and connect with the right audience. Much like Interesting Engineering or Wevolver, our mission is to bridge the gap between technology providers and industry professionals — turning innovation into visibility, and visibility into growth. 👉 Whether you are launching a new product, building your brand, or looking for global recognition, CTO Robotics is your media partner for exposure, credibility, and business opportunities.

All stories by: CTO Robotics

0 Comments