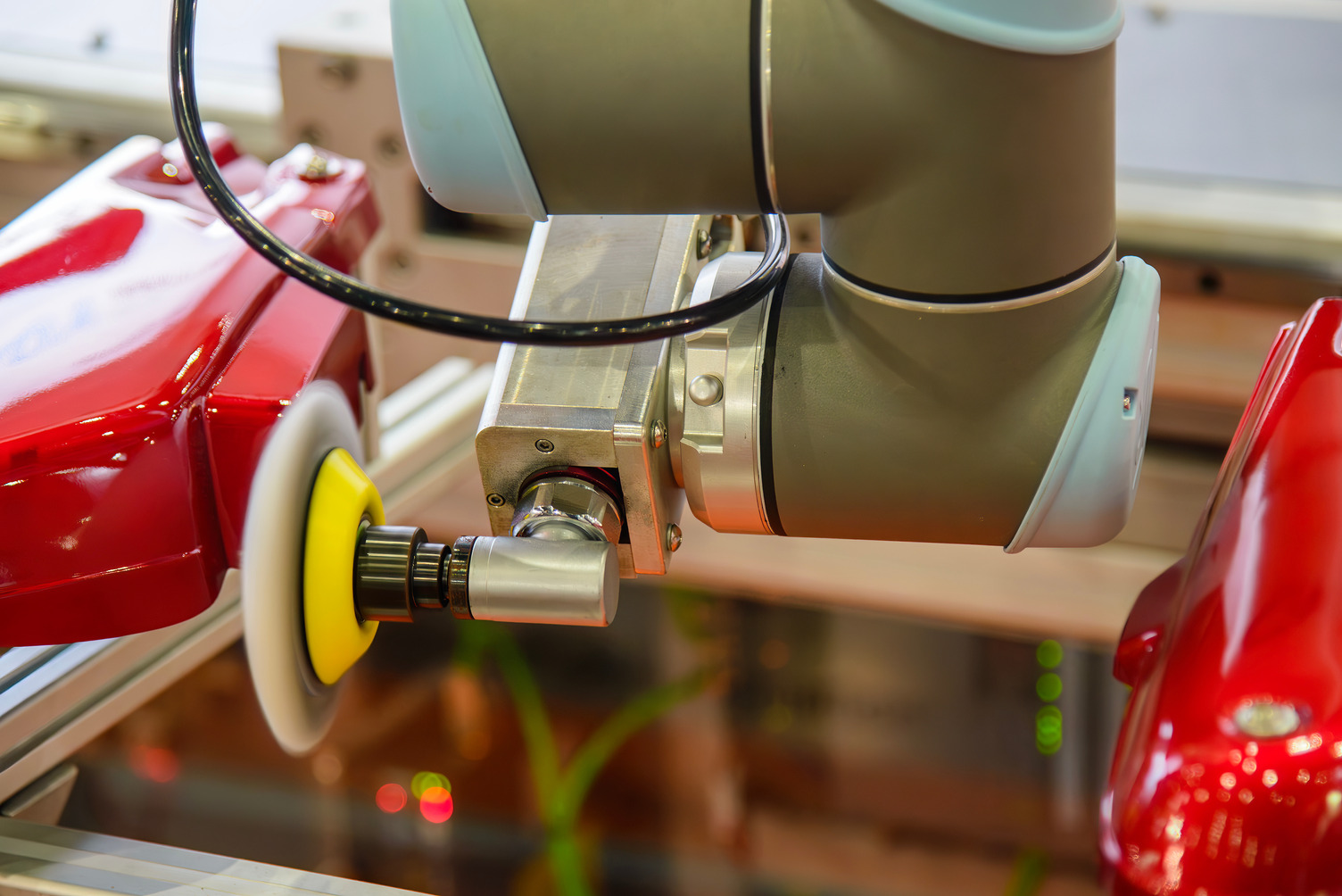

Robotic grinding and robotic material removal processes have been adopted by manufacturers around the world because of the many productivity benefits they provide. When compared to manual processes, robotic grinding offers a more versatile and streamlined way to improve operations.

Robotic grinding and robotic material removal processes have been adopted by manufacturers around the world because of the many productivity benefits they provide. When compared to manual processes, robotic grinding offers a more versatile and streamlined way to improve operations.

From iron castings to diesel engine blocks, robotic grinding and finishing is an essential part of manufacturing processes for a wide range of parts as manufacturers constantly pursue higher levels of productivity and part quality

The Primary Challenges to Manual Grinding and Finishing

One of the main challenges manufacturers face in manual grinding and finishing processes is a lack of consistency in part quality. In the end, manual workers may be able to produce a part with the same quality as a robot, but the possibility of human error leaves room for inconsistencies that can directly detract from a manufacturer’s bottom line.

The other primary obstacle in manual processes is achieving fast, consistent throughput levels. Manual processes can be slow and unpredictable in comparison to what’s possible with automation, which not only lowers throughput but creates variations in throughput based on how long a worker must spend on each part.

The Benefits of Robotic Grinding and Finishing

There are many benefits that come with robotic automation of grinding and finishing. Robots are inherently repeatable, which addresses inconsistencies in throughput and part quality. Further, robots can work much longer hours without breaks, contributing to higher overall throughput levels.

In addition to higher, more consistent throughput and better part quality, robotic grinding and finishing creates short-term return on investment (ROI) and long-term reductions in operating costs. These results compound over time, as automating one process opens the door for further automation of other processes.

Manual vs. Robotic Grinding & Finishing

Robotic grinding and finishing improves quality, speed, safety, and consistency, while reducing long-term costs. Here’s how it compares to manual grinding and finishing.

| Category | Manual | Robotic |

|---|---|---|

| Consistency | Varies by operator fatigue/skill | Highly consistent & repeatable |

| Speed | Slower and varies by part/operator | Faster, steady, and programmable |

| Surface Quality | Depends on skill; hard to replicate exactly | Uniform across all parts |

| Safety | High risk (dust, vibration, repetitive strain) | Keeps workers out of hazardous environments |

| Cost (Short-Term) | Lower setup cost | Higher upfront investment |

| Cost (Long-Term) | Higher labor and rework costs | Lower due to automation and reduced scrap |

| Flexibility | High for small batches or custom jobs | High with proper programming and tooling |

| Tool Wear Control | Inconsistent | Optimized through force control and monitoring |

| Data & Traceability | Difficult | Easy to integrate with tracking and analytics systems |

| Uptime | Limited by human shifts and breaks | 24/7 potential with minimal downtime |

| Complex Geometry | Challenging and inconsistent | Handles complex parts with CAD-to-path and sensors |

| Environmental Control | Open environment, more dust/vibration | Easier to contain within a robotic cell |

The benefits of robotic grinding and finishing are clear. Essentially, robotic automation of grinding and finishing allows manufacturers to produce more parts with a higher quality at a lower cost.

When compared to manual processes, robotic automation offers many well-defined benefits for manufacturers that need to improve robotic grinding and finishing processes.

CTO Robotics

CTO Robotics is a global media and consulting company dedicated to robotics, automation, artificial intelligence, and emerging technologies. We create high-impact content that reaches engineers, decision-makers, and innovators worldwide. Through articles, videos, social media campaigns, and community-driven storytelling, we help companies showcase their technologies, strengthen their brand, and connect with the right audience. Much like Interesting Engineering or Wevolver, our mission is to bridge the gap between technology providers and industry professionals — turning innovation into visibility, and visibility into growth. 👉 Whether you are launching a new product, building your brand, or looking for global recognition, CTO Robotics is your media partner for exposure, credibility, and business opportunities.

All stories by: CTO Robotics

0 Comments