Sensors are getting smaller, smarter and more powerful. Find out how miniaturisation of sensors opens up new opportunities in IoT, medical technology, automotive and robotics. Our Olaf de Kok talks about the technical challenges, solutions and promising future of this innovative development.

The need for more compact, lightweight and efficient electronic devices has led to a clear trend towards miniaturisation of sensors. Olaf de Kok, Sales Director at Althen Sensors & Controls, talks about this important development within sensor and measurement solutions in this article.

Why miniaturisation?

The demand for smaller sensors arose decades ago with the introduction of compact electronic devices such as mobile phones, laptops and wearables. Smaller sensors have become essential in sectors such as medical care, IoT, automotive and industrial automation. Available space in applications such as cars and robotics is limited, making compact sensors a necessity.

Sensors suitable for miniaturisation

According to Olaf, the following sensors are most suitable for miniaturisation:

- Pressure sensors: medical applications and industrial monitoring.

- Acceleration sensors (IMUs and gyroscopes): robotics, automotive and aerospace.

- Temperature sensors: IoT and precision industry.

- Position and displacement sensors: robotics and medical devices.

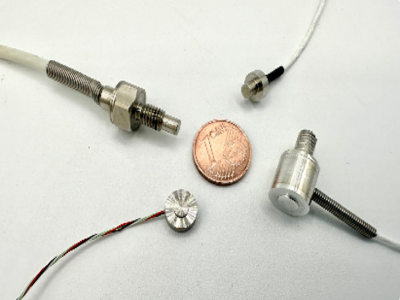

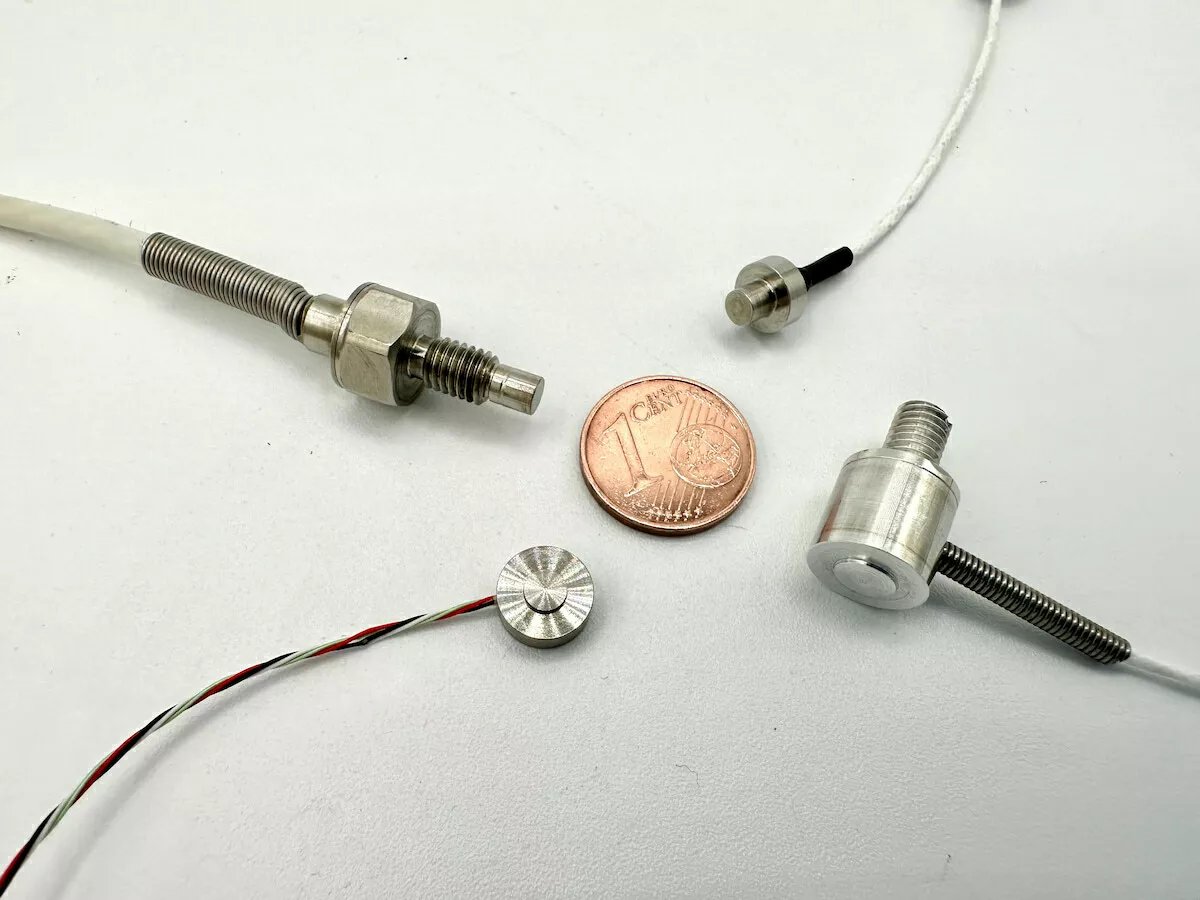

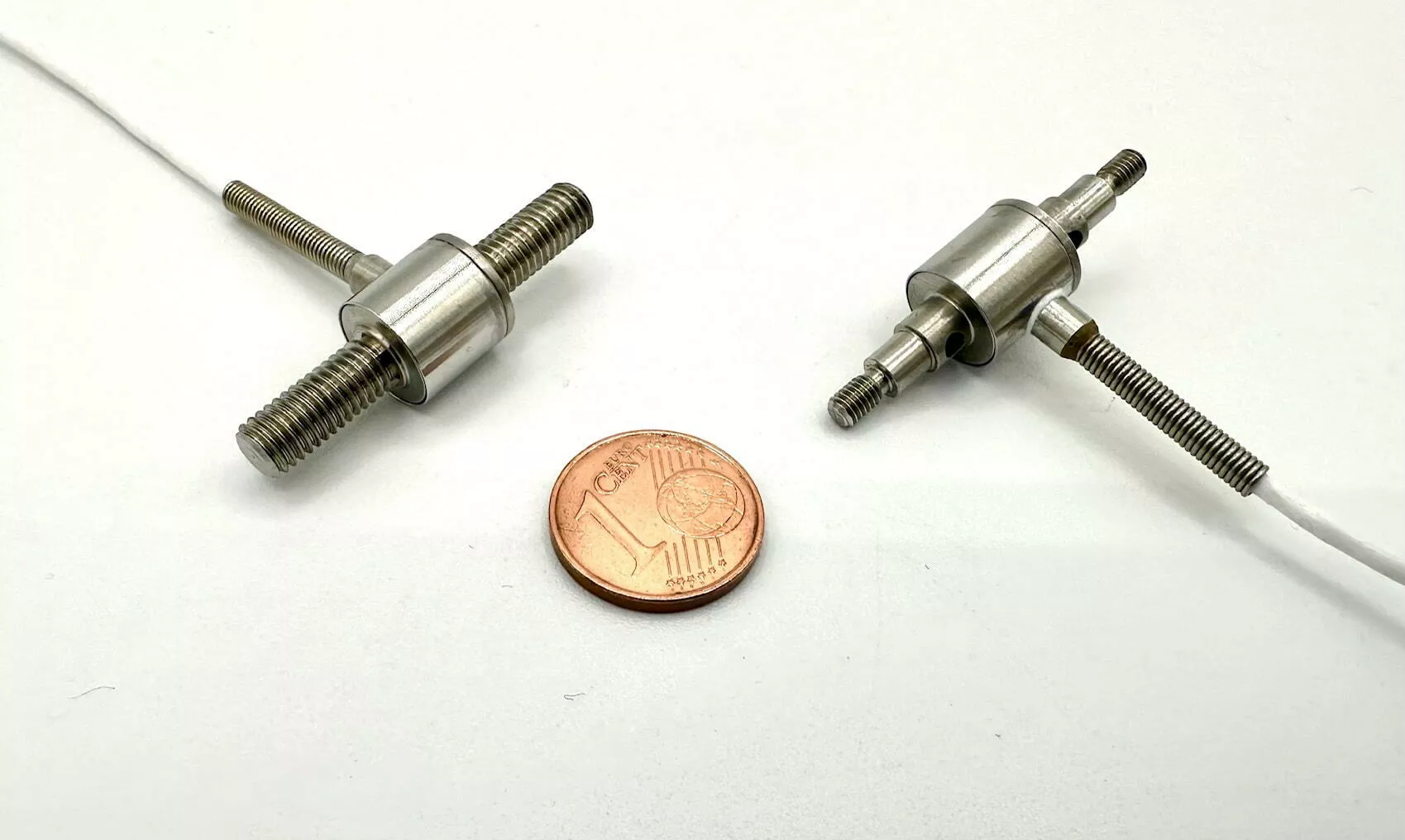

- Force sensors and strain gauges: biomechanical applications and precision industrial instruments.

Technical challenges and solutions

Miniaturisation involves several technical challenges:

- Precision and reliability: smaller sensors must offer the same measurement accuracy as their larger variants. Advanced signal processing and filtering play a crucial role here.

- Robustness: thanks to better materials and advanced encapsulation techniques, miniature sensors are increasingly resistant to external influences such as vibrations and temperature changes.

- Energy consumption: energy-efficient electronics and wireless power techniques allow sensors to become smaller without reducing their performance.

- Production complexity: manufacturing smaller sensors is complex, but thanks to MEMS technology, high-precision mass production can be achieved.

Current state of technology

Currently, sensors can be produced at micrometre and even nanometre scales thanks to MEMS and nanotechnology. Althen Sensors & Controls already offers miniature pressure sensors, acceleration sensors and force sensors for high-performance applications. Integrated sensors with wireless connectivity and built-in AI functionalities are also booming.

New possibilities thanks to smaller sensors

CTO Robotics

CTO Robotics is a global media and consulting company dedicated to robotics, automation, artificial intelligence, and emerging technologies. We create high-impact content that reaches engineers, decision-makers, and innovators worldwide. Through articles, videos, social media campaigns, and community-driven storytelling, we help companies showcase their technologies, strengthen their brand, and connect with the right audience. Much like Interesting Engineering or Wevolver, our mission is to bridge the gap between technology providers and industry professionals — turning innovation into visibility, and visibility into growth. 👉 Whether you are launching a new product, building your brand, or looking for global recognition, CTO Robotics is your media partner for exposure, credibility, and business opportunities.

All stories by: CTO Robotics

0 Comments