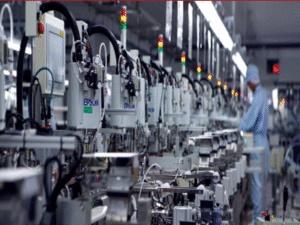

The path to success in robotic grinding and finishing may not always seem straightforward. Achieving return on investment (ROI) for all robotic systems and maximizing productivity are among the top priorities of just about any manufacturing setting, but there are common pitfalls when it comes to robotic grinding and finishing.

The path to success in robotic grinding and finishing may not always seem straightforward. Achieving return on investment (ROI) for all robotic systems and maximizing productivity are among the top priorities of just about any manufacturing setting, but there are common pitfalls when it comes to robotic grinding and finishing.

Following proven best practices can help ensure the implementation and ongoing automation of grinding and finishing processes delivers the intended results.

6 Tips for Robotic Grinding and Finishing

While there are many things you can do to improve robotic grinding and finishing processes, there are six main ways that may have the greatest impact.

1. Control the force of grinding and finishing systems

Controlling the force of robotic grinding and finishing systems not only makes for a safer work environment, but it can also help improve product quality by ensuring the proper force is exerted at all times. Typically, force is controlled by fixed passive controls, variable passive controls, or feedback for active force control.

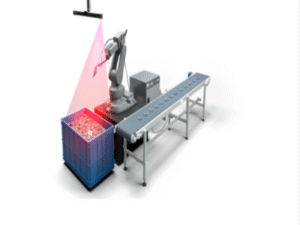

2. Use the right robot

All too often, the wrong size robot is used for robotic grinding and finishing applications. Assess the reach your robot will need and determine the right size. Likely a six-axis robot will be needed, but there are industrial and collaborative options available, depending on your specific application.

3. Use the right grinding equipment

There are a lot of considerations that go into choosing the right robotic equipment and this can sometimes lead to oversights on the basic grinding and finishing equipment. Be sure you have enough horsepower and find the correct balance between rigidity and flexibility in the contact wheel. Like many things, finding the right abrasive is an iterative process, so it’s important to take the time and ensure you find the right grinding and finishing equipment for the job.

4. Program with precision

Precision is key for quality, efficiency, and safety in the robotic grinding and finishing process. You can utilize CAD-to-Path software to guide the robot through an accurate path. If you go the manual route for teaching the robot, ensure the points are precise and fine-tuned for repeatability. Lastly, you’ll want to optimize speed, pressure, and tool RPM to prevent burns, undercutting, and uneven finish

5. Effectively manage dust and debris

Keeping a clean grinding and finishing station is crucial to keep the process running smoothly. Abrasive tools should be cleaned and replaced when necessary. A vacuum system should be put in place to collect dust and debris.

6. Don’t automate all at once

Automating all of your processes at one time only increases the risks that one small mistake could have big consequences on productivity and ROI. Try automating a portion of your grinding or finishing process first, and building on small success to eventually achieve fully automated production.

Controlling the force of grinding and finishing systems, using the right robot, using the right grinding equipment, and automating one process at a time are some of the best practices for robotic grinding and finishing.

Finding success in robotic grinding and finishing may seem difficult, but there are tried and true methods for achieving the results you desire.

CTO Robotics

CTO Robotics is a global media and consulting company dedicated to robotics, automation, artificial intelligence, and emerging technologies. We create high-impact content that reaches engineers, decision-makers, and innovators worldwide. Through articles, videos, social media campaigns, and community-driven storytelling, we help companies showcase their technologies, strengthen their brand, and connect with the right audience. Much like Interesting Engineering or Wevolver, our mission is to bridge the gap between technology providers and industry professionals — turning innovation into visibility, and visibility into growth. 👉 Whether you are launching a new product, building your brand, or looking for global recognition, CTO Robotics is your media partner for exposure, credibility, and business opportunities.

All stories by: CTO Robotics

0 Comments