AstraZeneca Unveils Massive Investment in US Manufacturing for Future Innovation

In a significant move poised to reshape the landscape of pharmaceutical manufacturing, AstraZeneca has announced a monumental $2 billion investment to bolster its production capabilities in Maryland. This strategic expansion is not just about increasing capacity; it signals a clear commitment to adopting cutting-edge technologies and smart manufacturing principles, directly impacting the future of automation and robotics in the biotech sector.

The investment targets two key areas: a substantial expansion of its flagship biologics manufacturing facility in Frederick and the construction of an entirely new, state-of-the-art facility in Gaithersburg. The Gaithersburg site will be dedicated to the development and clinical supply of innovative molecules, crucial for accelerating the pipeline of new medicines into clinical trials. This emphasis on ‘state-of-the-art’ and ‘innovative molecules’ immediately brings to mind the integral role that advanced robotics, automation, and AI-driven processes will play.

Smart Manufacturing and Robotics: The Unseen Force Behind Biotech Growth

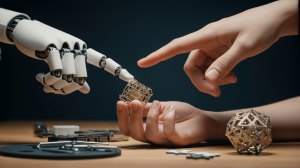

While AstraZeneca’s announcement focuses on drug development and manufacturing, the scale and nature of this investment inherently point towards a future rich in automation. The precision, sterile environments, and rigorous quality control required in biologics and innovative molecule production are prime candidates for robotic solutions.

Consider the potential applications: collaborative robots (cobots) could assist human operators in complex assembly tasks or sensitive material handling, minimizing contamination risks. Mobile robots (AMRs) could streamline logistics within these expansive new facilities, transporting raw materials and finished products efficiently and safely. Machine vision systems, powered by AI, would be indispensable for defect detection, quality assurance, and ensuring compliance with stringent regulatory standards.

Moreover, the concept of a ‘state-of-the-art facility’ aligns perfectly with Industry 4.0 paradigms, integrating Industrial IoT sensors, digital twins for process optimization, and AI algorithms for predictive maintenance and enhanced operational efficiency. This investment is not just building factories; it’s building smart factories designed for the future of medicine, where intelligent automation will be at the core of innovation and output.

Maryland’s Biotech Corridor Set for an Automation Revolution

AstraZeneca’s $2 billion commitment will undoubtedly solidify Maryland’s position as a global biotech hub. More importantly for our industry, it will accelerate the demand for advanced manufacturing technologies, fostering innovation in robotics, industrial automation, and smart factory solutions. As these facilities come online, they will set new benchmarks for precision, efficiency, and flexibility in pharmaceutical production, driven by the very technologies ctorobotics.com champions.

This is a clear signal that the biotech industry is increasingly embracing the power of automation and AI to scale production, enhance quality, and bring life-saving innovations to market faster. For robotics and automation providers, AstraZeneca’s investment represents a significant opportunity and a preview of the high-tech future taking shape in advanced manufacturing.

Connect with the CTO ROBOTICS Media Community

Follow us and join our community channels for the latest insights in AI, Robotics, Smart Manufacturing and Smart Tech.

CTO Robotics

CTO Robotics is a global media and consulting company dedicated to robotics, automation, artificial intelligence, and emerging technologies. We create high-impact content that reaches engineers, decision-makers, and innovators worldwide. Through articles, videos, social media campaigns, and community-driven storytelling, we help companies showcase their technologies, strengthen their brand, and connect with the right audience. Much like Interesting Engineering or Wevolver, our mission is to bridge the gap between technology providers and industry professionals — turning innovation into visibility, and visibility into growth. 👉 Whether you are launching a new product, building your brand, or looking for global recognition, CTO Robotics is your media partner for exposure, credibility, and business opportunities.

All stories by: CTO Robotics

0 Comments