While not a magic bullet, artificial intelligence (AI) is changing the game for manufacturers faced with ongoing labor shortages, decreased productivity and quality control, and an unpredictable supply chain exacerbated by growing consumer demands.

While not a magic bullet, artificial intelligence (AI) is changing the game for manufacturers faced with ongoing labor shortages, decreased productivity and quality control, and an unpredictable supply chain exacerbated by growing consumer demands.

Increasingly sophisticated AI is already being used in nearly every industry—from automotive and food & beverage to metal fabrication and plastic molding—to power predictive systems, increase robot capabilities, improve the precision of machine vision and help businesses optimize their processes to improve quality and reduce waste.

The future is here—and we’re just getting started. As AI becomes more powerful, robots and other machines can quickly learn what they need to do to perform given tasks without expensive and difficult-to-find AI experts. When coupled with decreasing hardware costs and clearer use cases demonstrating the benefits, deploying AI is an obvious choice for small and large companies alike.

“What was once costly, complicated and close to impossible without human workers is now possible—and happening today,” said Max Versace, the co-founder and CEO of Neurala, a Boston-based company that brings vision AI to the factory floor to help ensure quality inspection and prevent defects by teaching machines to perform tasks by repeatedly showing “good” data over a short time. “In fact, by 2032, AI will make manufacturing nearly unrecognizable, without requiring investments in new technology or AI-trained personnel or requiring manufacturers to give out their own data to Cloud providers. Everything will happen seamlessly, on premise, on low-cost hardware, and will be as easy to operate and immediate as a smart phone app.”

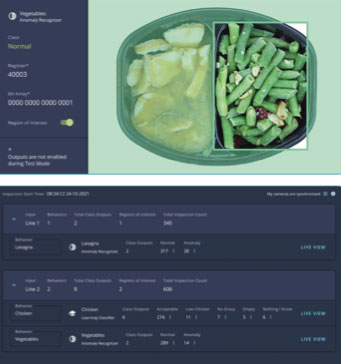

One happy Neurala customer is apetito, which prepares, packages and delivers more than 1 million frozen-ready meals a week across 14 production lines, primarily to retirement homes and hospitals. To offset growing customer complaints about meals missing ingredients or packaging issues such as improperly crimped or unsecured lids, apetito turned to automation to help with quality inspection. After earlier bouts with AI, apetito learned about Neurala’s Vision Inspection Automation (VIA) software.

“After a quick training that showing an AI-powered camera a few examples of what the meals should look like, the AI software can inspect 100% of the production and catch defects before the meals are sent to customers,” said Versace. “This improves productivity and quality without the need for AI experts. In the case of apetito, ensuring the customer receives the right meal, with all elements in the right proportions, is crucial, and AI makes it possible.”

AI helps eliminate product defects for machine manufacturers

Machines can also benefit from AI using other sensors outside of vision. Imagine a packaging machine that is creating tea bags or coffee pods for retail purchase, or other machines that package meat or manufacture plastic parts. In these cases, the machine—fundamentally a robot—has myriad types of sensors: besides cameras, it can sense pressure, temperature, torque, humidity, and all sorts of things that might resemble some of the very senses we have in our own body.

“We humans know when something is wrong with our body, but machines are not able to do that quite yet,” Versace said. “So, a packaging machine that is designed to operate 24/7, every day for 15 years, still have to rely on a human operator, and her interpretation of the sensor data, to understand if something is off. Having a human available at all times just isn’t possible, or efficient. As the apetito examples show, with the proper use of data AI can do those jobs, catching any defects before they reach customers. In this case, AI can be trained to learn what a good production cycle “feels like” for a machine, whose AI software is then able to alert human users without requiring constant oversight. That’s what we are fielding with Italian Industrial Machine manufacturer IMA, a world-leader in packaging machines.”

AI and the Need for “Good” Data

As the use cases imply, data is extremely important for AI. “AI works much the same as humans work,” Versace said. “Imagine that you’re a child and your mother shows you a banana and tells you that it’s an apple, or shows you an apple and tells you that’s a pear. That would confuse you for sure, and it would be wrong.”

The same thing can happen with AI. “If you’re telling the AI the wrong thing, you’re basically lying to your system. You need to present good data to the AI. For instance, if you’re showing the robots healthy products, and then insert broken products into the healthy sample, then the AI is going to think, ‘Oh, this broken product is healthy, because you’ve just told me it’s healthy.’”

How you collect the data is equally as important. “We have seen customers take a snapshot of the products with a cell phone from different angles and under different lighting, and then give us the data to figure out,” he says. “That’s the worst thing you can do because it introduces a ton of variability in the data that is very different from the true deployment scenario. To prevent these unpredictable variables, we need to collect the data professionally, and to do so, we collaborate with most of our customers using system integrators who know how to acquire data and how to deploy it in a customer-ready solution at the customer site. Then we can properly teach the machines the proper tasks under the right variables.”

CTO Robotics

CTO Robotics is a global media and consulting company dedicated to robotics, automation, artificial intelligence, and emerging technologies. We create high-impact content that reaches engineers, decision-makers, and innovators worldwide. Through articles, videos, social media campaigns, and community-driven storytelling, we help companies showcase their technologies, strengthen their brand, and connect with the right audience. Much like Interesting Engineering or Wevolver, our mission is to bridge the gap between technology providers and industry professionals — turning innovation into visibility, and visibility into growth. 👉 Whether you are launching a new product, building your brand, or looking for global recognition, CTO Robotics is your media partner for exposure, credibility, and business opportunities.

All stories by: CTO Robotics

0 Comments